Gazitepe, Fabrikalar Cd NO:41, 34582 Silivri, İstanbul

Dmk Kalıp

Contact Information

-

-

: 9.00 to 18.30

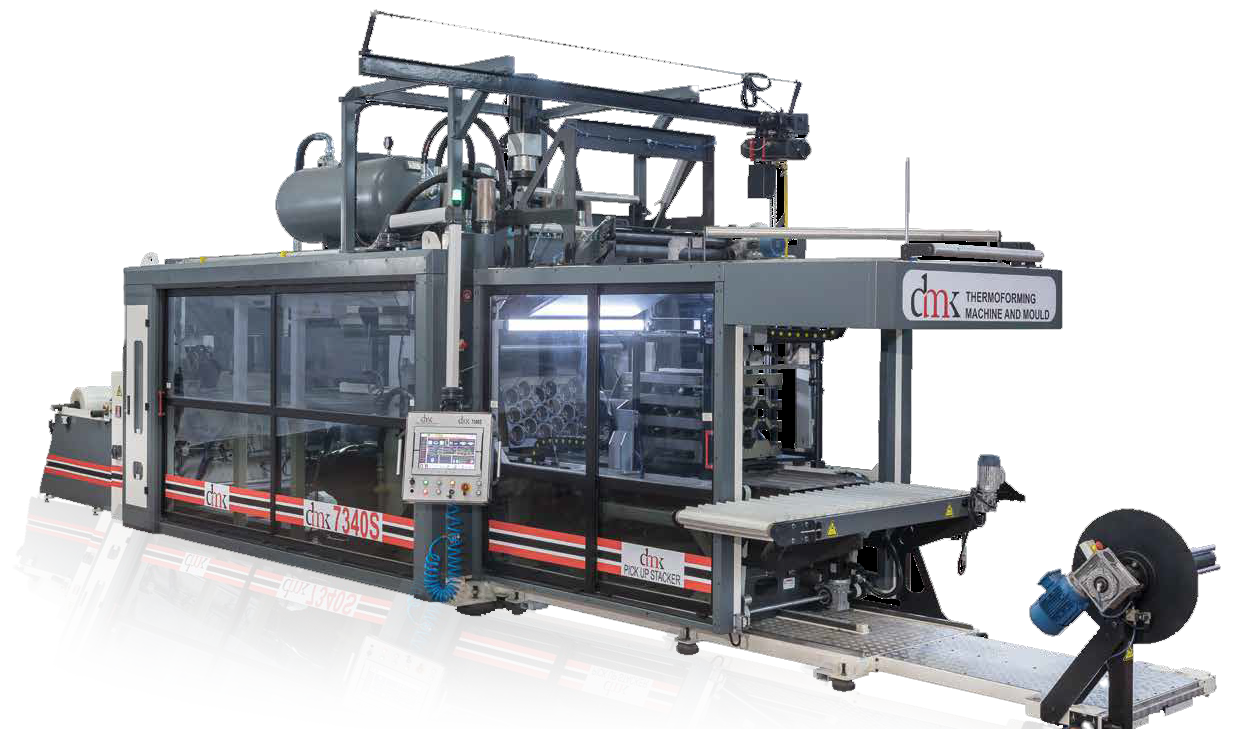

DMK offers a quality-oriented production process, presenting products and services in the most flawless manner. DMK, by providing technology-integrated production that meets its customers' needs 100%, is on its way to becoming a 'Global Brand in Thermoforming.'

.jpg)

.jpg)

.jpg)

The story of the DMK team begins a quarter of a century ago with the production of thermoforming molds.